Stock code:839470

Hotline  +86-021-56197282

+86-021-56197282

+86-021-56197282

+86-021-56197282

Plastic sintered filtration products

UHMWPE

Product Introduction

Product Introduction

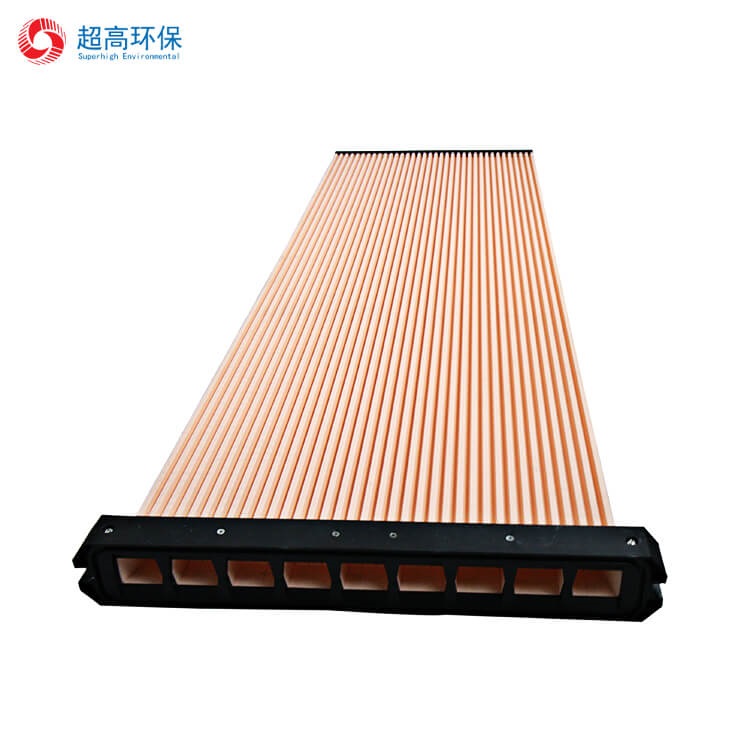

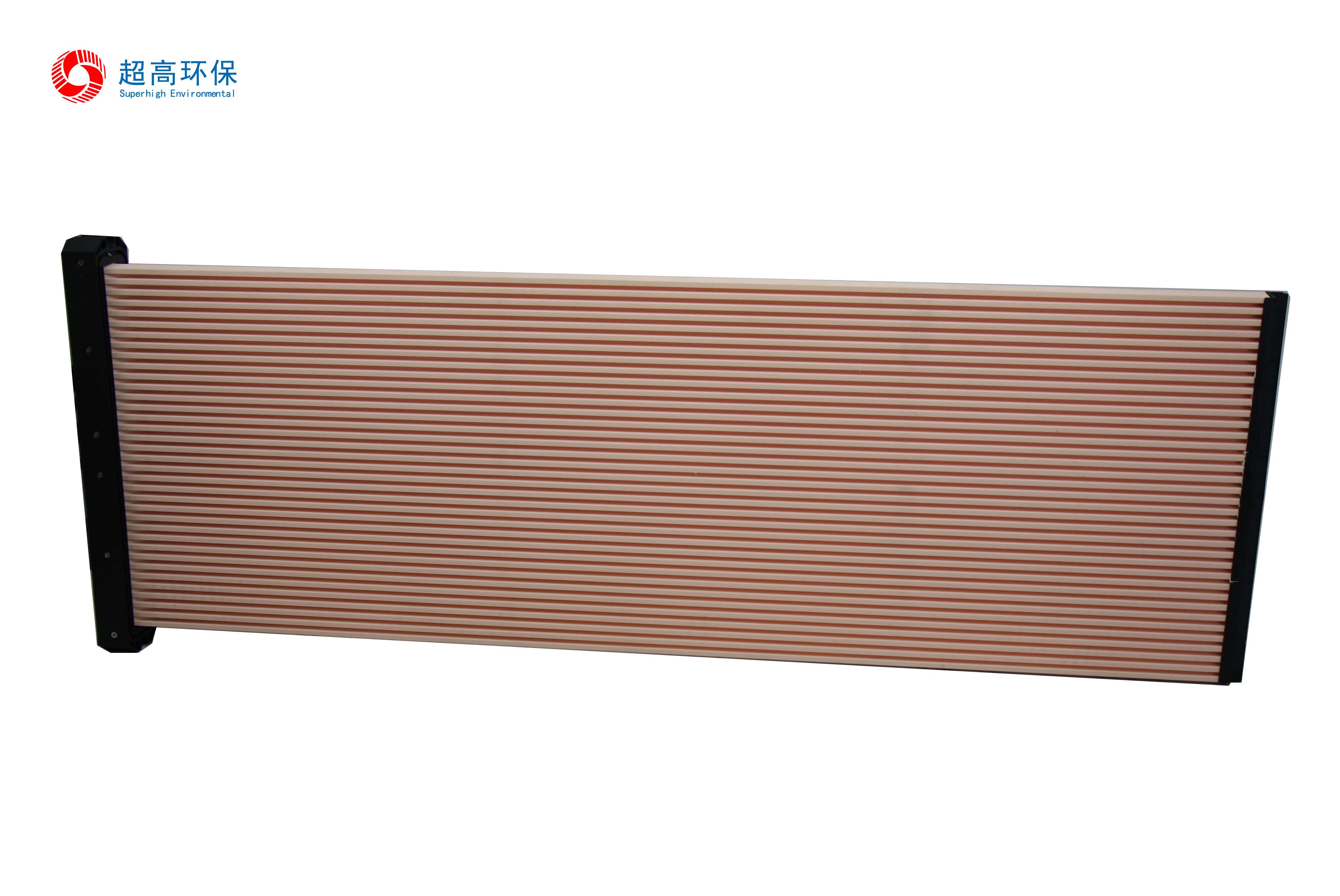

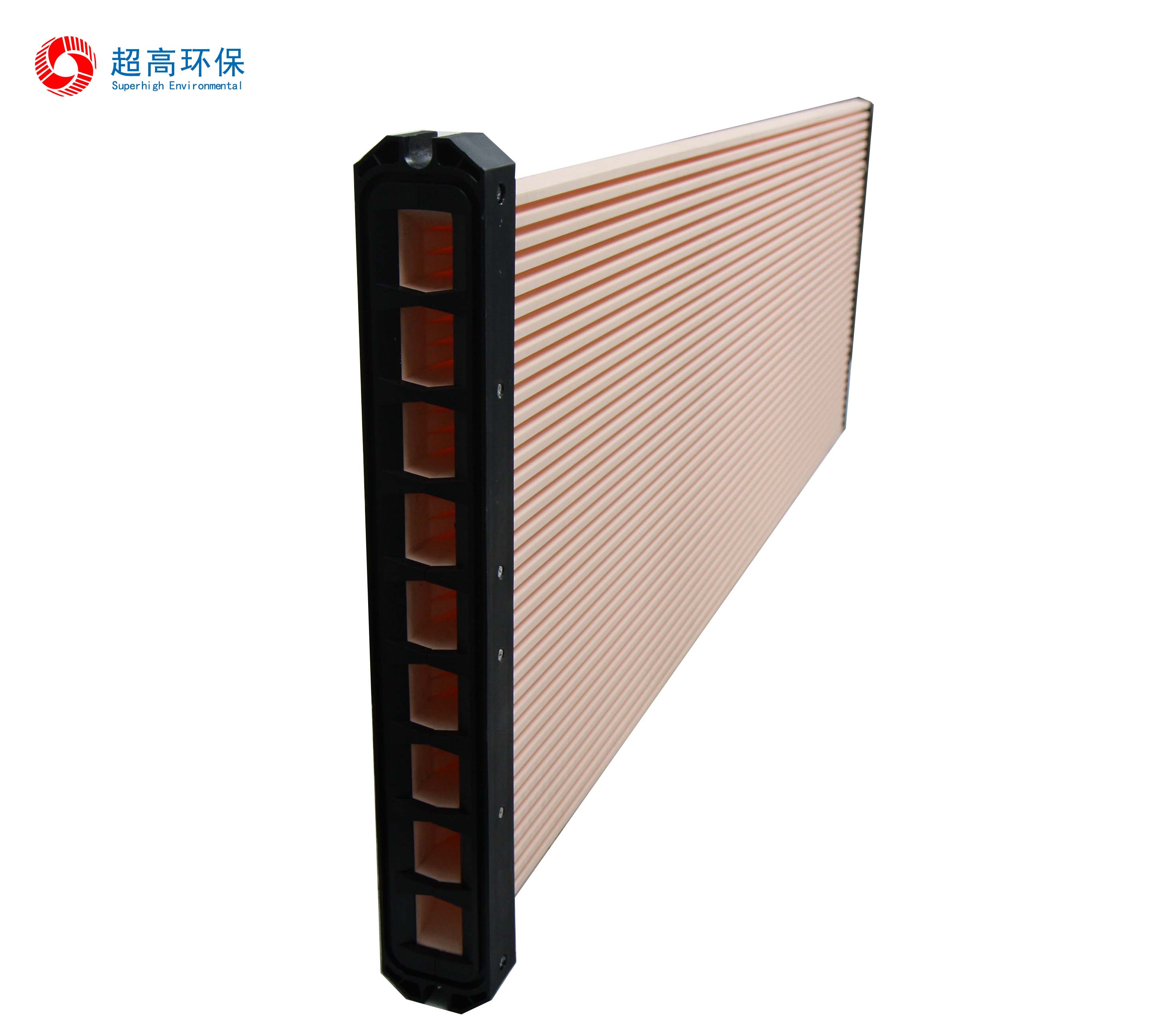

The sinter-plate is the main filter element in the sinter board dust catcher and carries out the gas-solid separation task in plastic sintered plates for dust removers.

Sinter-plate filter adopts polymer composite and is formed by being sintered by a special high temperature furnace. The formed matrix has a complete micron-sized micropore, which only allows gas to pass through and intercepts microparticle at its surface to achieve dust removal filter effect. At the same time,

enhanced PTFE resin film is covered at the surface of sinter-plate, which has strong self-clean function and can effectively avoid dust adhesion during work. By the use of gas recoil technology, it can automatic remove the dust and keep stable wind resistance loss.

The structure of sinter-plate is usually rectangular. The filter part is wavy plate structure, which can increase the effective area of dust removal.

Product Superior

Product Superior

Performance feature

High filtration accuracy ————— Micron-sized filter aperture can effectively capture the dust above 0.1μm; The capture efficiency can reach to 99.9999% for the dust above 10μm.

Better air permeability —————— Advanced sintering technology and improved ingredient formulation are adopted to ensure the uniform micropore inside sinter-plate, contributing to better connectivity and breathability.

Large filtration area —————— Large filtration area is designed to wave. The filter area of single-plate (HY-SSB-001)can reach to 7 square meters, twice or trice times filter area than filter bag in the same volume.

High dust capture efficiency ———— High filtration accuracy contributes to high dust capture efficiency. Its exhaust dust concentration can reach to 10mg/Nm3.

Strong self-cleaning capacity ————— Steel structure makes anti-blowing gases directly applied to the powders attached to the filter surface, contributing better counter blowing effect. New generation strengthen PTFE coating is adopted to make the surface of sinter-surface dense, smooth, which makes higher filtration accuracy and significantly improves dust-cleaning performance.

Stable pressure loss ————— Super self-cleaning ability ensures that the filtration pressure loss is small and more stable.

Strong acid and alkali resistance ———— Special macromolecular composites can withstand high temperature corrosion of strong acid and alkali.

Excellent moisture resistance and oil resistance ————— The substrate material of sinner-plate has excellent moisture resistance and oil resistance. Covered with PTEE coating, it has higher moisture-proof and oil resistivity and gather water vapor with acid into water to remove.

Excellent mechanical properties ————— It has high strength and toughness and can withstand the repeated shock of several thousand high pressure gas every day.

Long service life ———— Excellent mechanical properties; Strong acid and alkali resistance; Perfect self-cleaning effect; After achieving normal service life, sinter-plate filter still has the same filter effect as new products by the regeneration of the wear coating.

Product Performance

Product Performance

Plastic sintered filtration productsApplication of Polyethylene

Plastic sintered filtration productsApplication of Polyethylene

(6)Application Examples

-

1

1 -

2

2 -

3

3